This is our wagon in September 2017 outside Ackroyd's Mill in Otley, West Yorkshire. Wm. Ackroyd and Sons had a 4 ton Garrett undertype, which was photographed at this location formerly on the A65 through Otley but now a side road.

Please join me on a tour around the wagon, this is a new tour having completed the original one many years ago. Can you spot any differences?

We will start at the front near side where the clinker door is open and the fire has just been lit. The operating rod for the ashpan prevents the door from opening out fully and bashing into the boiler cladding. When the wagon is running on the road the fire piles up against the clinker door if you have got the depth right. The white lagged pipe leads from the feedwater heater to the boiler and the small black pipe is the drain from the feedwater heater into the ashpan. One of the mudholes, used for washing out the boiler is located over the ashpan door hinge.

We move along past the front wheel and arrive at the pump. This is driven from a gear on the end of the crankshaft; the drive for the lubricator is taken from the pump eccentric and transmitted to the lubricator by the red rod above the pump body. The blanking plate held on by three nuts is for where the dynamo for the electric lighting will be mounted.

Behind the pump is the left hand chain sprocket on the end of the countershaft. The differential gear is contained within the countershaft/gearbox casing and there are two roller chains, one to drive each rear wheel. The box mounted on the chain guard is for providing a drip feed of oil onto the roller chain. The large casting to the right of the chain sprocket is the end of the adjustable radius rod, which allows the spacing between the rear axle and the countershaft to be altered to maintain the correct tension in the chains.

We come to the rear of the wagon where the water tank is located. The wire bound rubber hose is for the waterlifter, originally intended for obtaining clean water from roadside streams, this does not get much use these days since many road improvements have resulted in the culverting of watercourses and the raising of road levels above streams to reduce gradients.

The back of the wagon. Here we can see the back of the water tank. The cable above the towing bracket is for the trailer brake. The number plate would be illuminated by a lamp on the bracket situated at the right side of the tank.

Moving back towards the front of the wagon we can see the gauge glass on the side of the water tank.

Next, we come to the right hand side of the engine. The small gear on the chain sprocket is for the speedometer drive. The drive cable is in position but the gear has been disengaged. The large domed cap is on the end of the crankshaft and is used for adjusting the four Timken bearings on the crankshaft. Just above the sag in the speedometer cable is the gear change mechanism. The large rod running alongside the chassis is for the footbrake.

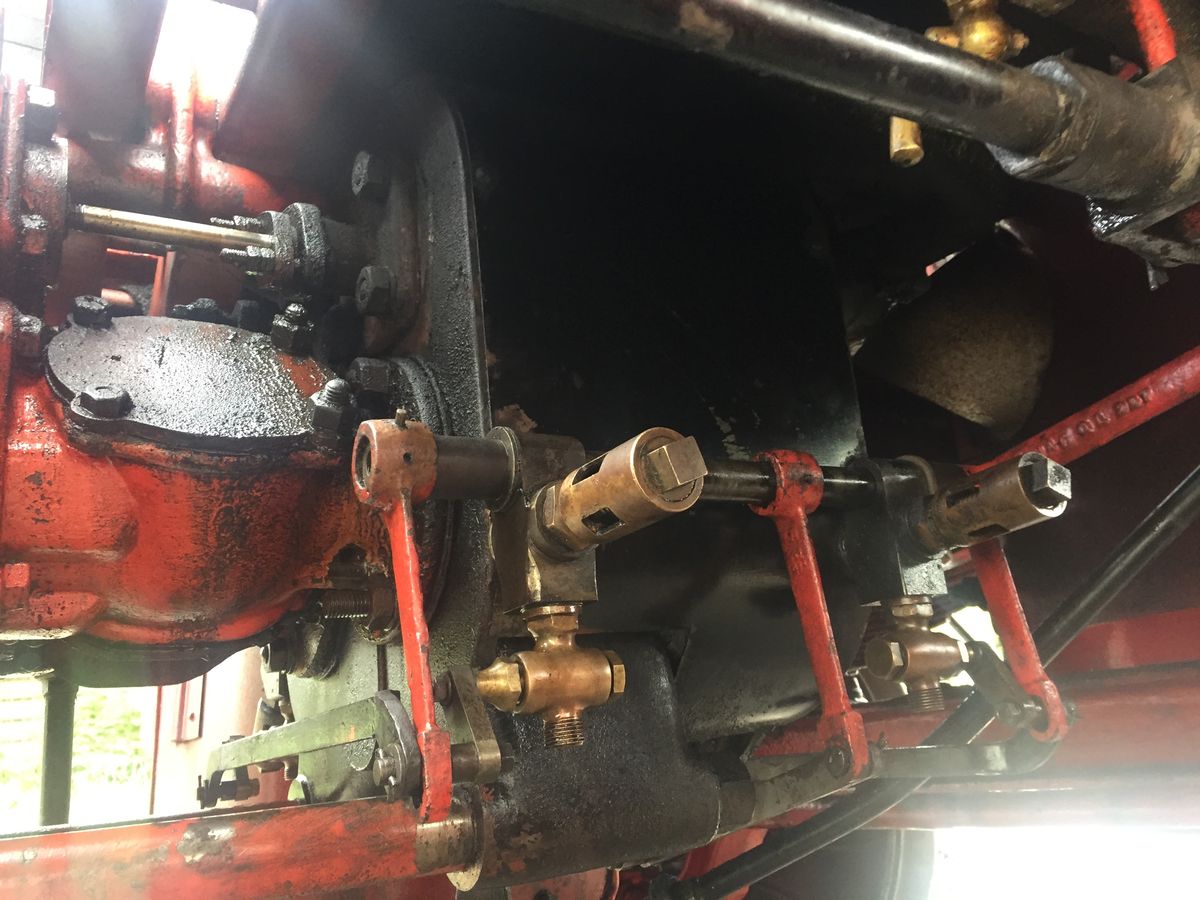

Climbing under the wagon we can see the cylinder block with the pressure relief valves and drain cocks.

We are now back at the front of the wagon; items to note are: no door on the driver's side, the large steering box, the oil sidelight and electric headlamp, the speedometer on the cab stanchion and the cover plates in the front wheels. We are looking for a pair of Oldfield "Dependence" Type 439 oil-electric lamps so that we can make up a full electric lighting set if anyone can provide any complete lamps or the electric conversion parts that would be much appreciated.

The weights painted on the side of the wagon are UW - unladen weight, AWF - axle weight front, AWB - axle weight back.

We now take a peek, over the apron into the cab before we go round the other side and climb in.

The driving position. The controls are: centre left - injector steam valve, top left - blower valve, bottom left - injector clack, stop valve lever, water gauge, steering wheel, pump control lever, foot brake, accelerator pedal, handbrake and reversing lever.